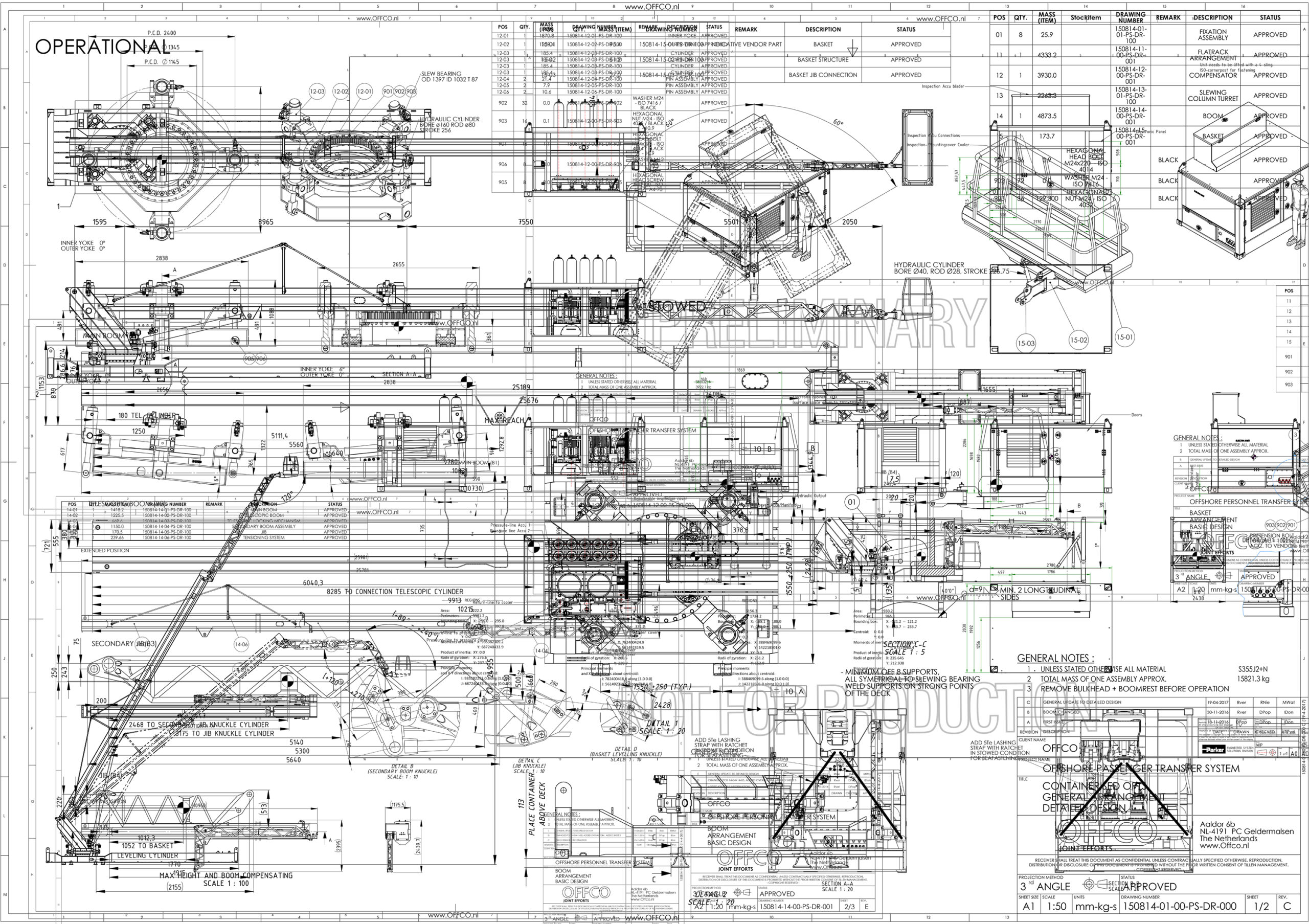

All relevant information is gathered and organised. This can be in the form of blueprints or a simple photograph of the object in question.

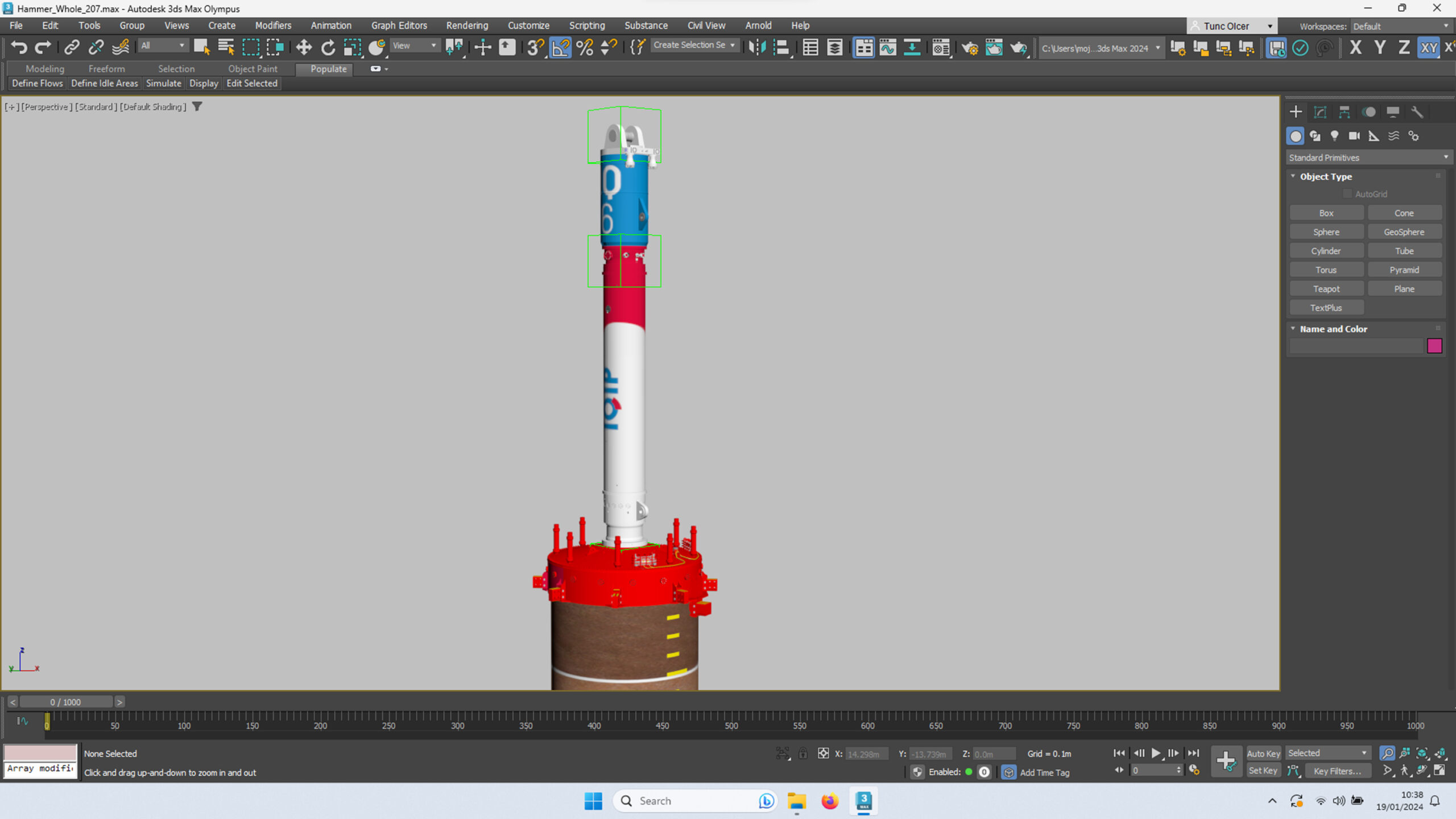

All parts are then modeled in 3DSMAx using the blueprints as construction templates.

The parts are then fitted into subassemblies.

Subassemblies are fitted together to form larger functional parts.

The finished model is then exported as a usable format.

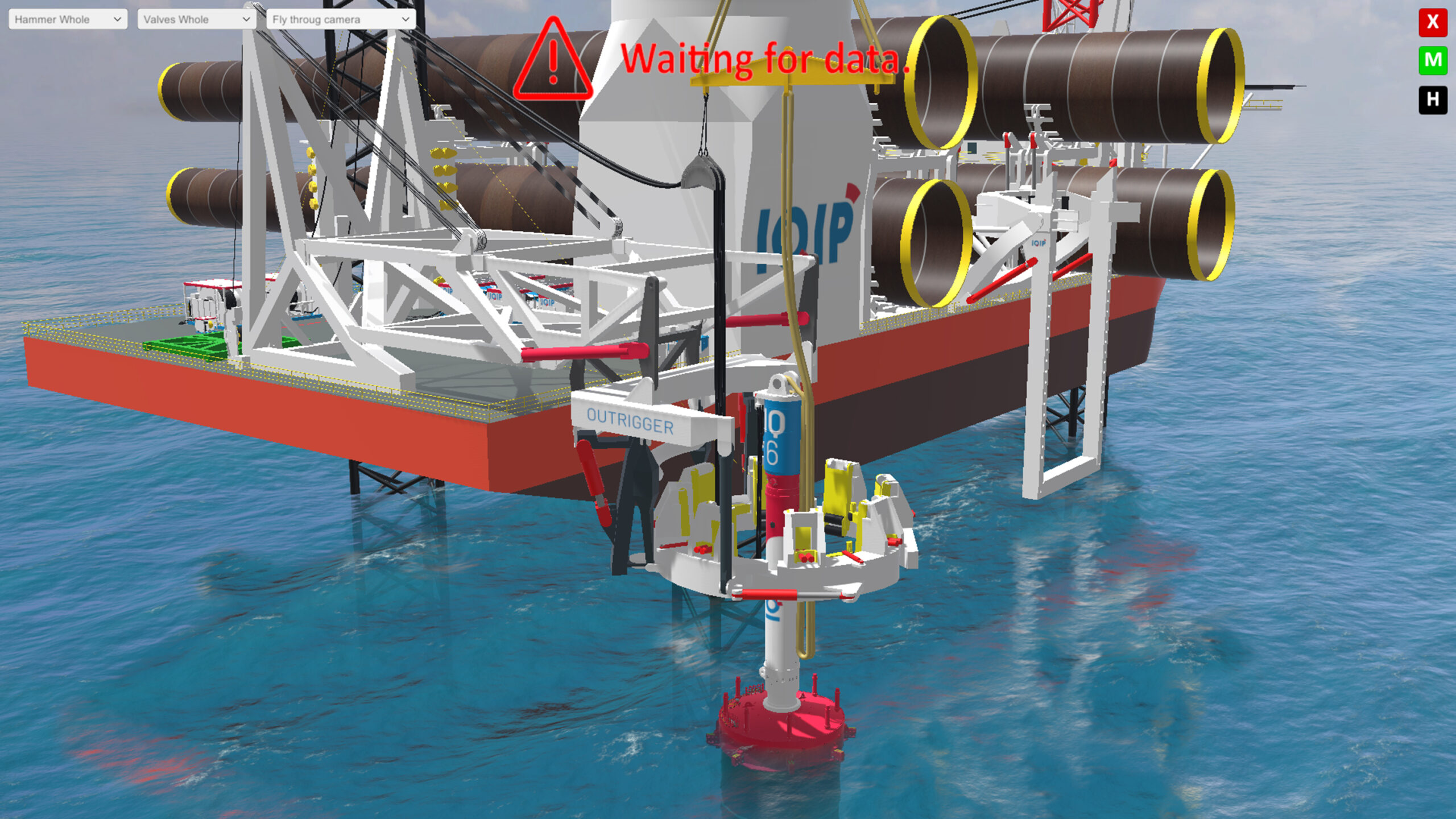

All models are imported and a scene is built for the application.

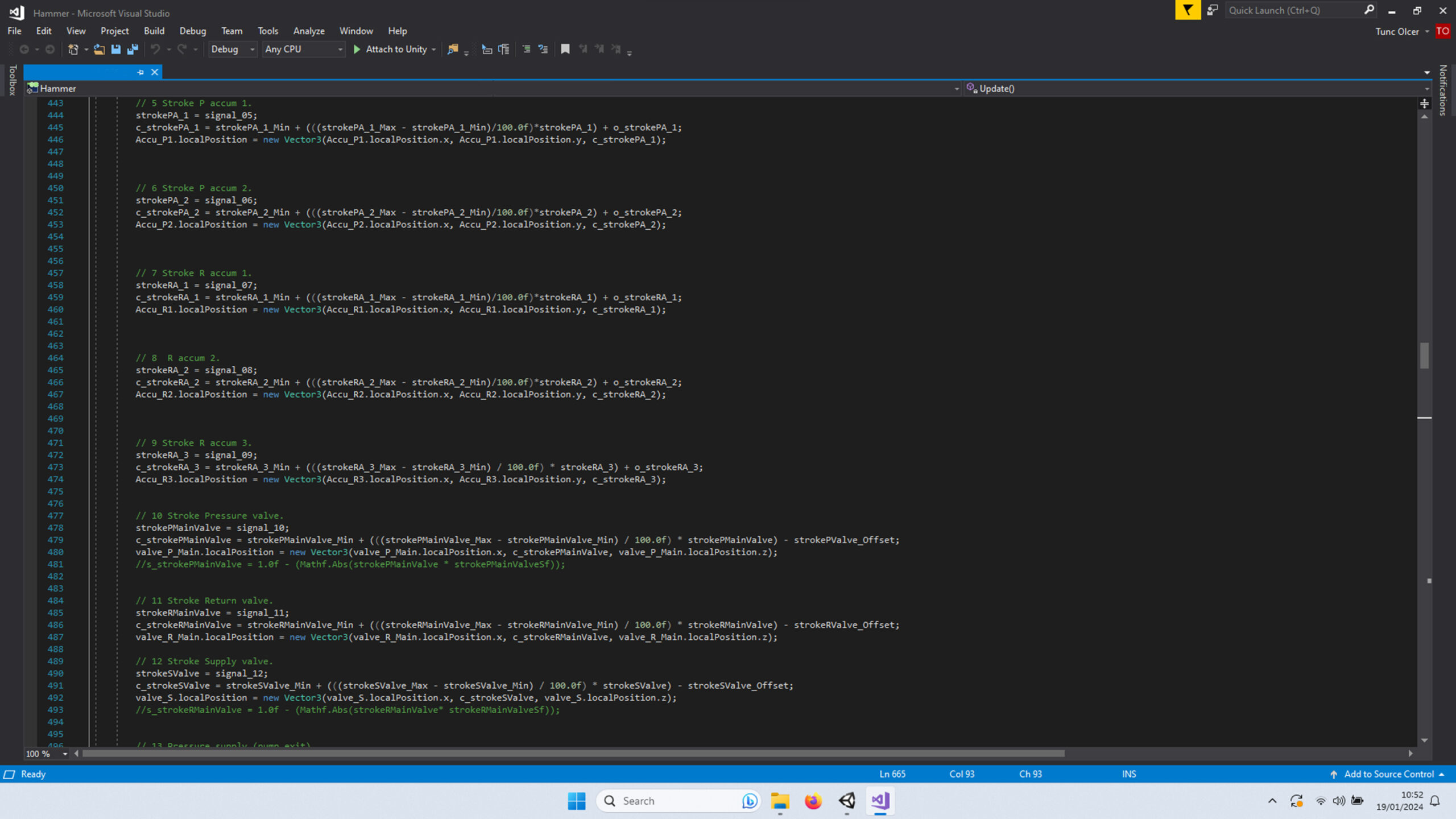

Code is written for the application including behaviors and interactions of the objects and communication with external information sources. This information can come from almost any external application.

The application is then compiled and ready to use.

Click here to link to an external site with the application in use : https://nl.mathworks.com/company/user_stories/iqip-uses-hil-for-virtual-commissioning-of-offshore-machines.html